Vertical Field IoT technology

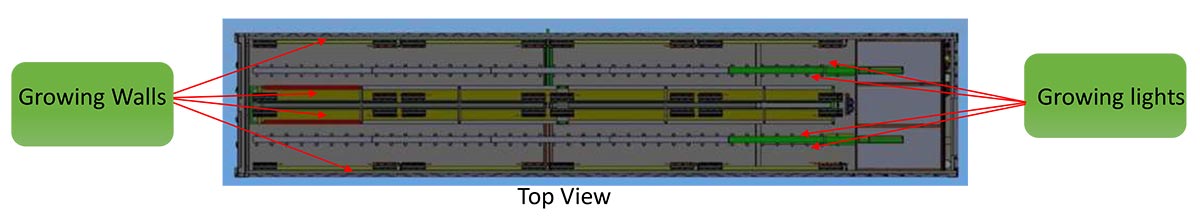

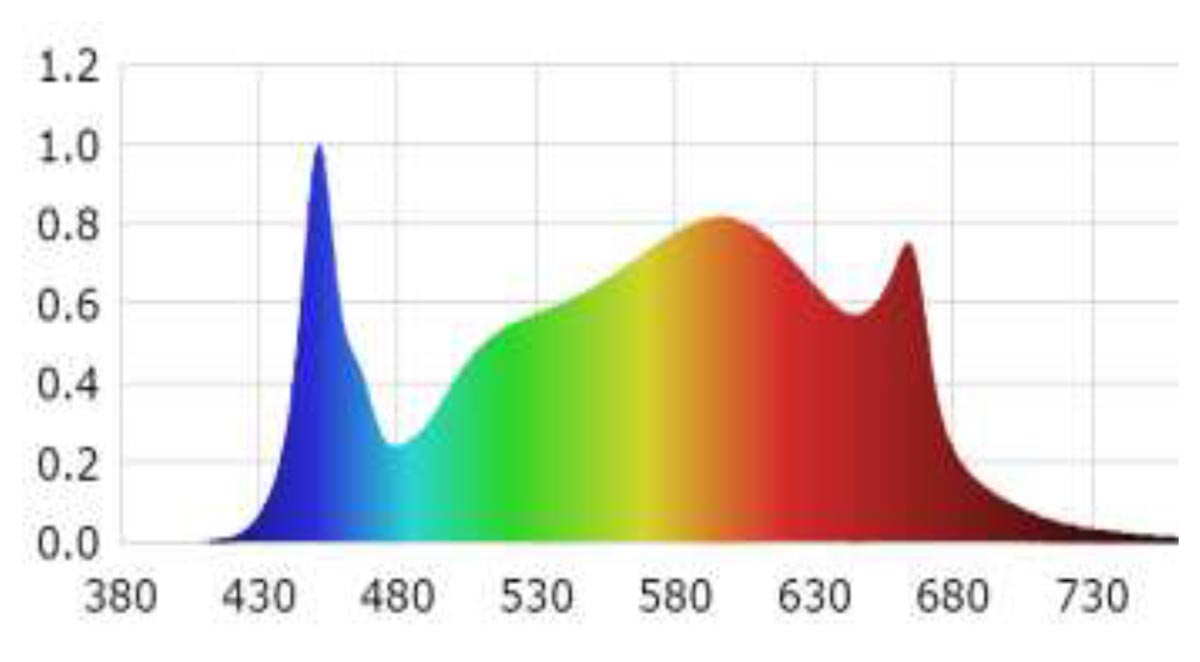

Growing lights system

The growing lights system contains 160 LED bars located 30cm away from the plants and there are 40 LED bars on each "wall". The LED bars are highly energy efficient with 106.894/37.45=2.85umol/W.

Photonetric Parameters

Luminous Flux: 7152.12lm

EEI: 0.07

PAR: 22.542 W

Efficiency: 190.98 lm/W

Energy Efficiency Class: A++ (EU 874-2012)

PPF: 106.894 umol/s

Radiant Power: 22.920 W

R/B: 1.8

Photons1: 17.615 umol/s(400~500m)

Photons2: 43.683 umol/s(600~700m)

Electric Parameters

Voltage: 229.80V

Power Factor: 0.9270

Current: 0.1750A

Frequency: 50.00Hz

Power: 37.45W

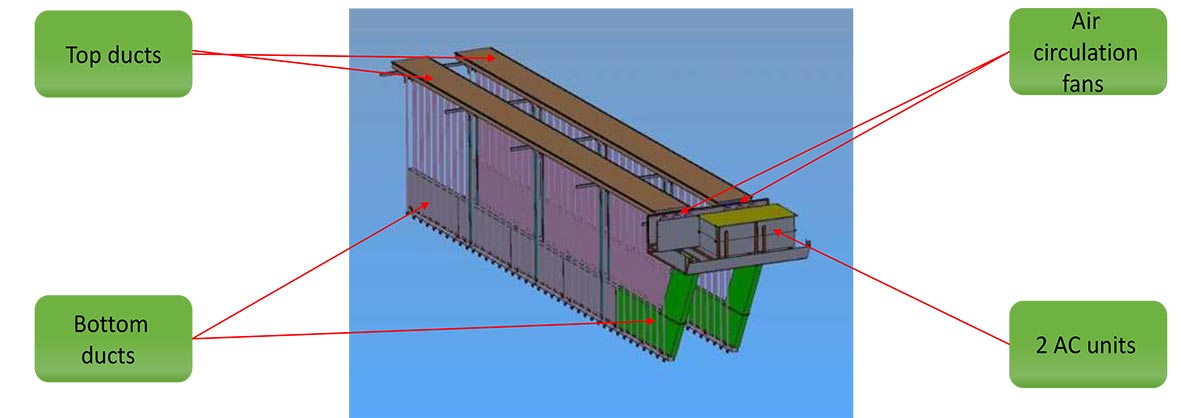

Climate Control system

To ensure optimal and even temperature and air circulation inside the container we designed climate control system based on 2 Mitsubishi AC units located in double ceiling structure and top, bottom air circulation ducts. The top ducts distribute cooled/heated air from the AC units and the bottom ducts return the air back to the AC.

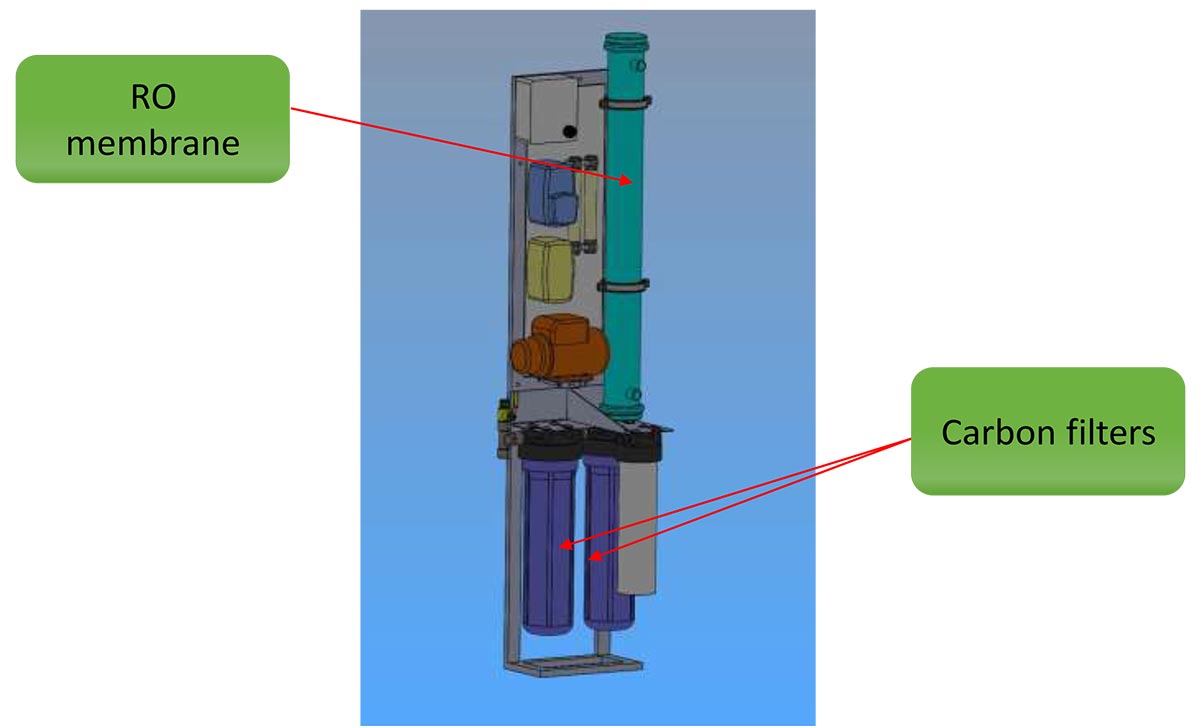

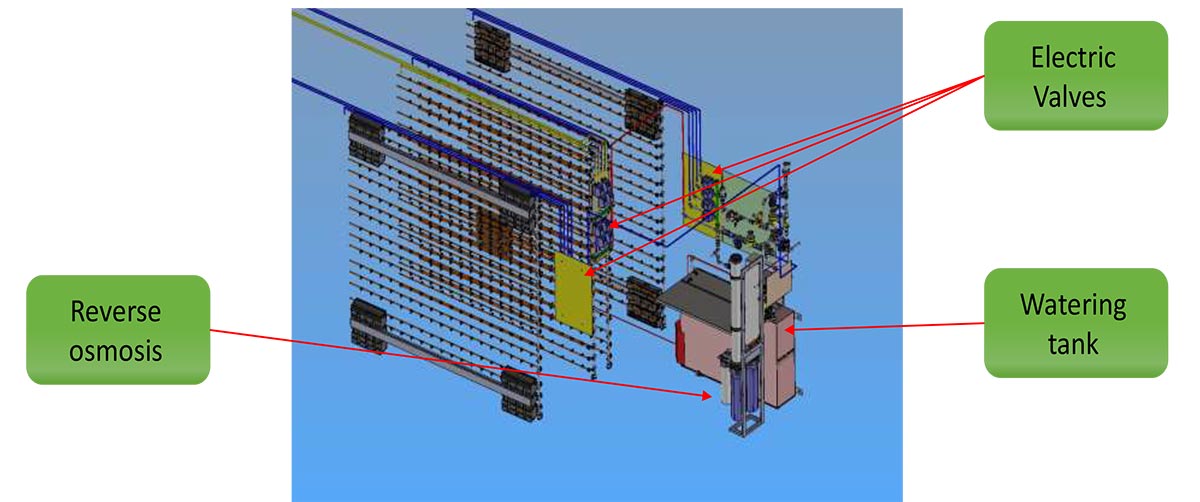

Reverse Osmosis

In order to ensure continuous operation without dependence on water quality, the units contain a reverse osmosis water filtering system. Using this system for irrigation allows precise and even fertilisation. Flow rate: 150-200 litres per hour.

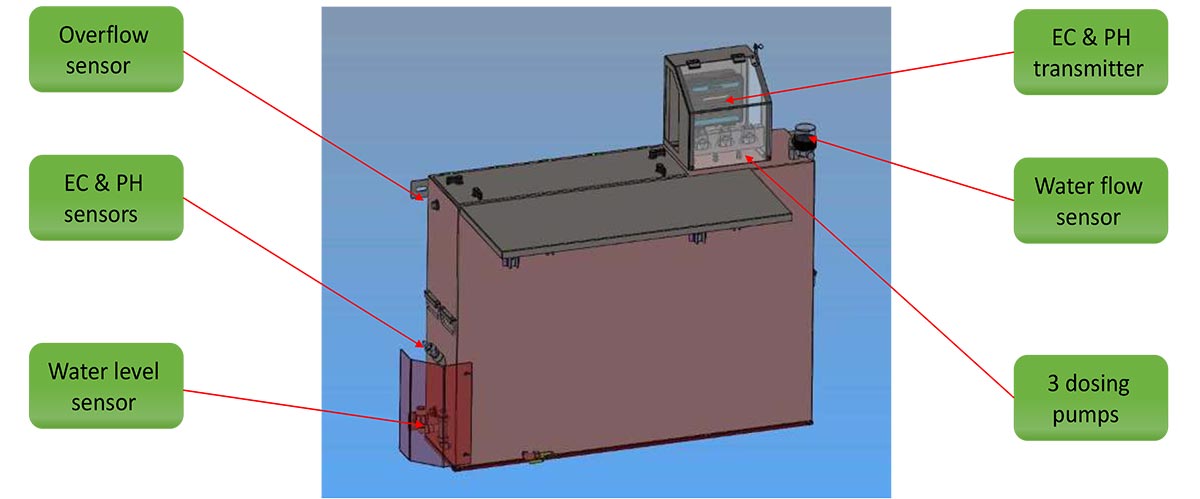

Fertilisation system

After the water has been filtered, it flows into the watering tank. Three dosing pumps add fertilizer and acid until the required EC and PH levels are reached. Throughout the process water level, EC and PH are monitored and in case of a fault the fertilization process stops, and an error is displayed.

Irrigation system

Fertilized water from the watering tank is distributed between the 16 growing fields, each filed receives the exact irrigation based on the plants' maturity.

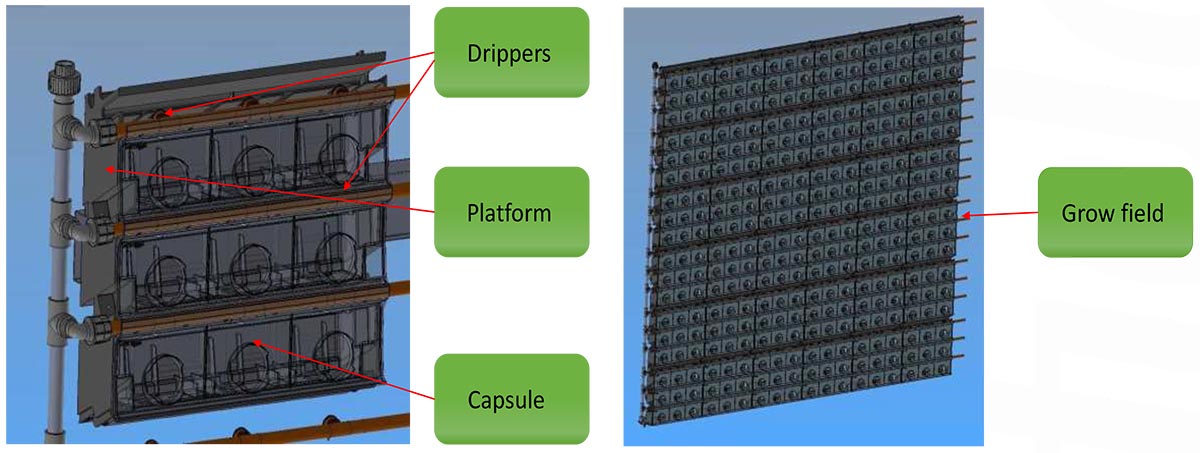

Field Structure and Irrigation system

Each growing field has 36 modules (6X6) that contain 3 agriculture capsules. Each capsule is designed to hold 3 plants which therefore produces 324 plants per field. The water is distributed precisely using droppers located directly above each plant.